Analytics in Construction: Reducing Delays and Improving Margins

Analytics in Construction: Reducing Delays and Improving Margins

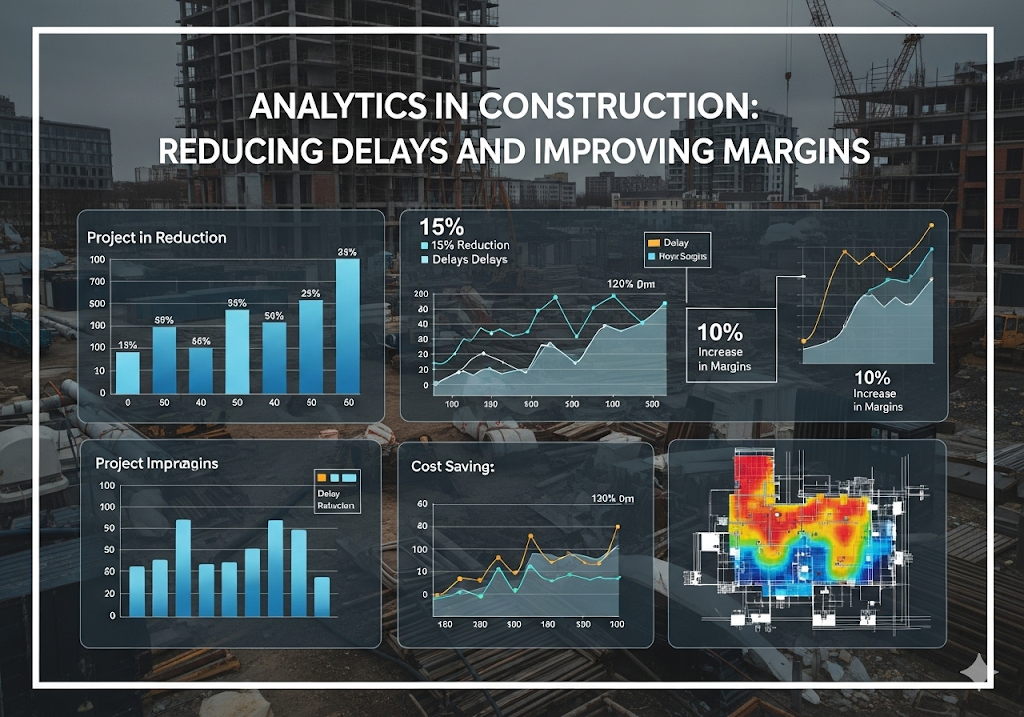

The construction industry has always been one of the most complex and high-stakes sectors in the global economy. From infrastructure megaprojects to commercial real estate developments, construction projects involve intricate coordination of labor, materials, equipment, financing, and regulatory compliance. Yet, despite the billions of dollars invested annually, the industry has long struggled with two chronic issues: delays and thin margins.

According to McKinsey, large construction projects often take 20% longer to finish than scheduled and run up to 80% over budget. In an industry where profit margins often hover around 2–5%, such overruns can be devastating. The solution lies in embracing analytics—transforming how construction firms plan, monitor, and execute their projects.

This blog explores how analytics is revolutionizing construction, helping companies reduce delays, improve operational efficiency, and ultimately protect margins.

The Challenges of Traditional Construction Management

Before understanding the value of analytics, it’s important to recognize the structural challenges construction projects face:

-

Fragmentation of Stakeholders: Owners, contractors, subcontractors, suppliers, and regulators all interact in complex webs. Miscommunication is frequent.

-

Unpredictable External Factors: Weather, labor disputes, supply chain disruptions, and regulatory approvals can derail even the best-laid plans.

-

Data Silos: Project data often sits in spreadsheets, disconnected software systems, or even on paper logs, making it hard to gain a holistic view.

-

Reactive Decision-Making: Many construction managers rely on intuition or outdated reports instead of real-time insights, leading to slow course corrections.

The result is a cycle of delays, cost overruns, rework, and disputes. This is where analytics becomes a game-changer.

How Analytics Reduces Delays in Construction

Analytics enables construction companies to move from reactive firefighting to proactive management. Here’s how:

1. Predictive Scheduling and Resource Allocation

Traditional Gantt charts often fail to capture real-world complexities. With predictive analytics, project managers can model scenarios based on weather forecasts, labor productivity, and equipment availability. This allows them to:

-

Anticipate bottlenecks before they occur.

-

Reallocate resources dynamically.

-

Optimize crew assignments for efficiency.

For instance, if analytics predicts rain on critical pouring days, managers can reschedule tasks in advance, avoiding wasted labor and costly delays.

2. Supply Chain Visibility

Material shortages are a common source of delays. Analytics tools integrate procurement data with supplier performance records, shipping updates, and inventory levels. Companies gain:

-

Early alerts for potential shortages.

-

Insights into supplier reliability.

-

Better coordination of just-in-time deliveries.

This reduces the chances of crews waiting idly on-site due to missing materials.

3. Real-Time Progress Monitoring

IoT sensors, drones, and mobile apps now capture real-time data from construction sites. Analytics platforms process this data to show:

-

Actual progress vs. planned progress.

-

Productivity rates for crews and machinery.

-

Early signs of slippage in timelines.

Managers can make immediate adjustments, instead of discovering delays weeks later in monthly reports.

4. Risk Analysis and Contingency Planning

Analytics evaluates historical project data to identify risks—such as subcontractor defaults, weather delays, or design changes. With probabilistic models, firms can build contingency plans in advance, reducing disruptions when risks materialize.

How Analytics Improves Margins

Margins in construction are notoriously thin, so even small efficiency gains can translate into significant profitability. Analytics enhances margins by addressing cost leakages and enabling smarter decisions.

1. Cost Forecasting and Control

Instead of static budgets, analytics systems continuously update cost forecasts based on real-time inputs—material price changes, labor costs, or fuel consumption. Project managers can:

-

Spot cost overruns early.

-

Negotiate better supplier terms.

-

Reallocate budgets dynamically.

This ensures fewer surprises at project closeout.

2. Labor Productivity Insights

Labor accounts for a significant portion of construction costs. By analyzing productivity data, firms can:

-

Benchmark performance across teams.

-

Identify underperforming crews.

-

Adjust shift schedules for optimal efficiency.

For example, analytics might reveal that productivity drops by 20% during late-night shifts, guiding firms to prioritize daytime work.

3. Equipment Utilization Optimization

Heavy machinery is expensive to rent and maintain. Analytics platforms track equipment usage, idle time, and fuel consumption. Firms can:

-

Improve scheduling of machinery.

-

Reduce idle rentals.

-

Extend asset lifespans through predictive maintenance.

4. Reduction of Rework

Rework is a hidden margin killer—caused by design errors, miscommunication, or quality issues. Analytics tools integrate design models (BIM) with field data, identifying discrepancies early and preventing costly rework.

Case Example: Using Analytics to Save a Mega Project

Consider a hypothetical project—The Amira Towers in Riyadh, Saudi Arabia. The $500 million commercial project faced challenges with multiple subcontractors and tight deadlines. By implementing a construction analytics platform, the project team achieved:

-

30% reduction in schedule deviations by using predictive scheduling and weather-adjusted timelines.

-

15% improvement in labor productivity after identifying low-performing crews.

-

$10 million in cost savings from optimized equipment usage and reduced rework.

The result was on-time completion with margins above industry average—a powerful demonstration of analytics in action.

Key Analytics Tools and Technologies in Construction

Construction analytics is powered by a mix of technologies:

-

Business Intelligence (BI) Dashboards: Provide executives with a consolidated view of project health.

-

Building Information Modeling (BIM): Integrated with analytics to detect clashes and rework risks.

-

IoT and Sensors: Capture real-time site data—equipment usage, worker location, environmental conditions.

-

AI and Machine Learning Models: Predict project risks, delays, and cost overruns.

-

Cloud Data Platforms: Break down silos and enable collaboration across stakeholders.

Together, these technologies create a data-driven ecosystem for construction firms.

The Organizational Impact of Analytics in Construction

Adopting analytics is not just about tools; it requires cultural and organizational change:

-

Data-Driven Culture: Project managers and engineers must rely on data, not just gut feel.

-

Upskilling Teams: Training staff in data literacy, visualization, and interpretation is essential.

-

Cross-Functional Collaboration: Analytics enables tighter coordination between finance, procurement, design, and operations teams.

-

Executive Buy-In: Leadership must champion analytics adoption to ensure long-term impact.

Analytics in KSA’s Construction Boom

Saudi Arabia is experiencing one of the world’s largest construction booms under Vision 2030, with mega projects like NEOM, The Line, and Qiddiya. These ambitious projects involve billions in investment and aggressive timelines.

Analytics plays a crucial role in ensuring these projects succeed by:

-

Enabling real-time visibility for government stakeholders.

-

Managing risks in complex multi-billion-dollar supply chains.

-

Optimizing margins in a highly competitive contractor environment.

-

Ensuring sustainable building practices through resource efficiency.

For KSA-based contractors, adopting analytics is not optional—it’s a competitive necessity.

How Datahub Analytics Can Help

At Datahub Analytics, we specialize in helping construction companies harness the power of analytics to reduce delays and protect margins. Our services include:

-

Big Data Infrastructure for Construction: Building scalable platforms to capture and analyze site data.

-

Predictive Analytics Models: Forecasting risks, delays, and cost overruns.

-

Business Intelligence Dashboards: Real-time visibility into project KPIs.

-

Data Governance and Security: Ensuring compliance and protecting sensitive construction data.

-

Outsourcing Analytics Talent: Providing skilled data engineers and analysts to support projects.

Whether it’s integrating IoT data into dashboards, enabling predictive scheduling, or improving cost control, Datahub Analytics helps construction firms transform their project outcomes.

Conclusion

The construction industry has always been high-risk, with delays and razor-thin margins threatening profitability. But with analytics, companies can transform these challenges into opportunities. By leveraging predictive scheduling, real-time monitoring, risk analysis, and cost optimization, construction firms can deliver projects faster, safer, and at healthier margins.

In the context of Saudi Arabia’s ambitious Vision 2030 and global infrastructure investments, adopting analytics is no longer a luxury—it’s an imperative. The winners will be the firms that embed data into their culture, processes, and decision-making.

At Datahub Analytics, we’re committed to partnering with construction leaders to drive this transformation. By combining domain expertise with cutting-edge analytics solutions, we help companies build smarter, stronger, and more profitable futures.